Boy...it has been quite some time since I have blogged here! It feels good to be back! :)

Personally, I have an affinity towards handmade beads - all mediums. I don't know about you, but I cannot count the number of "subscribed lists" I have signed up for to arrive in my email inbox, but I do at least glance at each and every "blog type" email that pops up in my mailbox feed -- always on the lookout for inspiration.. One of my favorite's is the Interweave Blog.

A couple of weeks ago, Tammy Jones had a post related to 1-hour rings. In this post was a quick, down and dirty tutorial to make a sterling silver ring that resembled bamboo (if interested, here is the link to that blog post). The tutorial (by artist Elizabeth Ann Tokoly) starts with a sterling silver ring already soldered and formed. After reading through the steps involved, I felt a thick gauge wire would work best - so I grabbed 6 gauge.

I will say, the making of this ring took me 1 hour and 45 minutes - but that included forming the ring from such heavy stock - I had to anneal the metal several times just to get it formed for soldering. And then anneal several more times AFTER the soldering to get it round and to the correct size (why didn't I just grab 8 gauge?) :) Also, it is a bit cumbersome to saw the score lines around the ring - but it can be done.

Anyway, it is a COOL ring, which I have gifted to a friend. (Forgive the picture quality - I just took a quick picture for reference purposes only).

This technique would be AWESOME for a bangle - which I will try in the future. In the meantime, I thought I would try making a little bead using this technique. For this bead, I grabbed some thick-walled sterling tubing.

I roughly measured the bead length to 3/4".

Cut the tubing to size using my tube cutting jig and jeweler's saw.

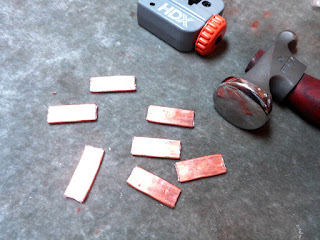

I made two little "end caps" for the bead by using my disc cutter and some scrap silver sheet - it's 18 gauge sheet, so it is thick.

I used medium silver solder paste to attach the first end cap to the tube - this is my set up.

After pickling - you can see that the excess overhang of the disc needs filing.

I used my ring clamp to stabilize the bead against my bench pin while I quickly filed away the excess silver.

The picture below is a bit blurry, but I filed the disc / end cap to be flush with the tubing.

Never EVER solder a hollow bead without first making a hole to allow steam to escape when soldering. Though I have not done it myself, I have read where nasty accidents can happen if the escape hole is not in place before closing up this hollow form. I simply put my bead in my vice and drilled a hole.

Second disc/end cap solder set up.

Pickled, then filed the second end cap / disc flush to the tubing/bead, and drilled the final hole.

Really hard to see in this picture, but I scored two parallel lines close to the ends of each bead, using my jeweler's saw - again using my ring clamp to hold the bead while sawing.

Now - this next step is the reason I used thick walled tubing. I used my tiny half round file to make four slight indentations around the middle of the bead.

I cleaned up the the bead with a pumice wheel on my flex shaft. (These are the pumice wheels I use).

Patina added (I use Midas Black Max - link here), buffed with steel wool, and tumbled. Liver of Sulfur works just as well, but Black Max is quicker and does not stink. :) Always a plus!

One more tiny tip (and of course, I forgot to take a picture). Before you tumble the bead, add the bead to a piece of wire (copper - it's cheap) and loop the ends. This will keep the shards of shot from getting stuck inside the bead while tumbling (this I have done...takes forever to release that shot!)

Now, this is not a perfect bead, but I rather like the organic look to this shape - would look great as a single bead on a bracelet, two beads for earrings, or even an entire chain if you have lots of time on your hands to create! Total time to make this bead for me (not including tumbling) was about 30 minutes. So, while this technique is a bit time consuming, it is handmade and definitely not made in China!

Anyway, the making of this bead was the bit of inspiration I need to kick off this brand new year. I wish you all a very Happy New Year!

Thanks for stopping by!