Carol Dekle-Foss

Does sawing metal seem like a daunting and difficult task? Or have you tried it and decided it wasn't for you for some reason? I hear ya! I used to hate it, the blade would drag on the metal and I would constantly break them. But, I was determined to get better at it and now its one of my favorite things to do in the studio. There are tons of tutorials and videos out there on how its done, but its one of those things you just have to do yourself and practice to master. So for this post, I'm going to share some basic techniques as well as a few things that have helped me along the way. I hope this motivates you to pick up that jewelers saw for the first time or give it a try again!

What you will need

Jewelers saw

Blades

Metal of choice

Artwork

Adhesive

Lubricant

Bench pin

Music and beverage of choice

My bench pin is a simple pre-notched one from Rio. I use a rusty clamp stolen from my hubby's toolbox to hold it in place. You can also customize your bench pin by cutting out special grooves for different sawing techniques. Here are some modifications I like and will probably do to my next bench pin. Michael David Sturlin's bench pin modifications. One of the most important tips is to have your bench pin placed at eye level so when you are sawing you are comfortable and not straining your back. You're gonna be here awhile, so play some of your favorite tunes and have your drink of choice nearby.

Here are the steps.

Step one

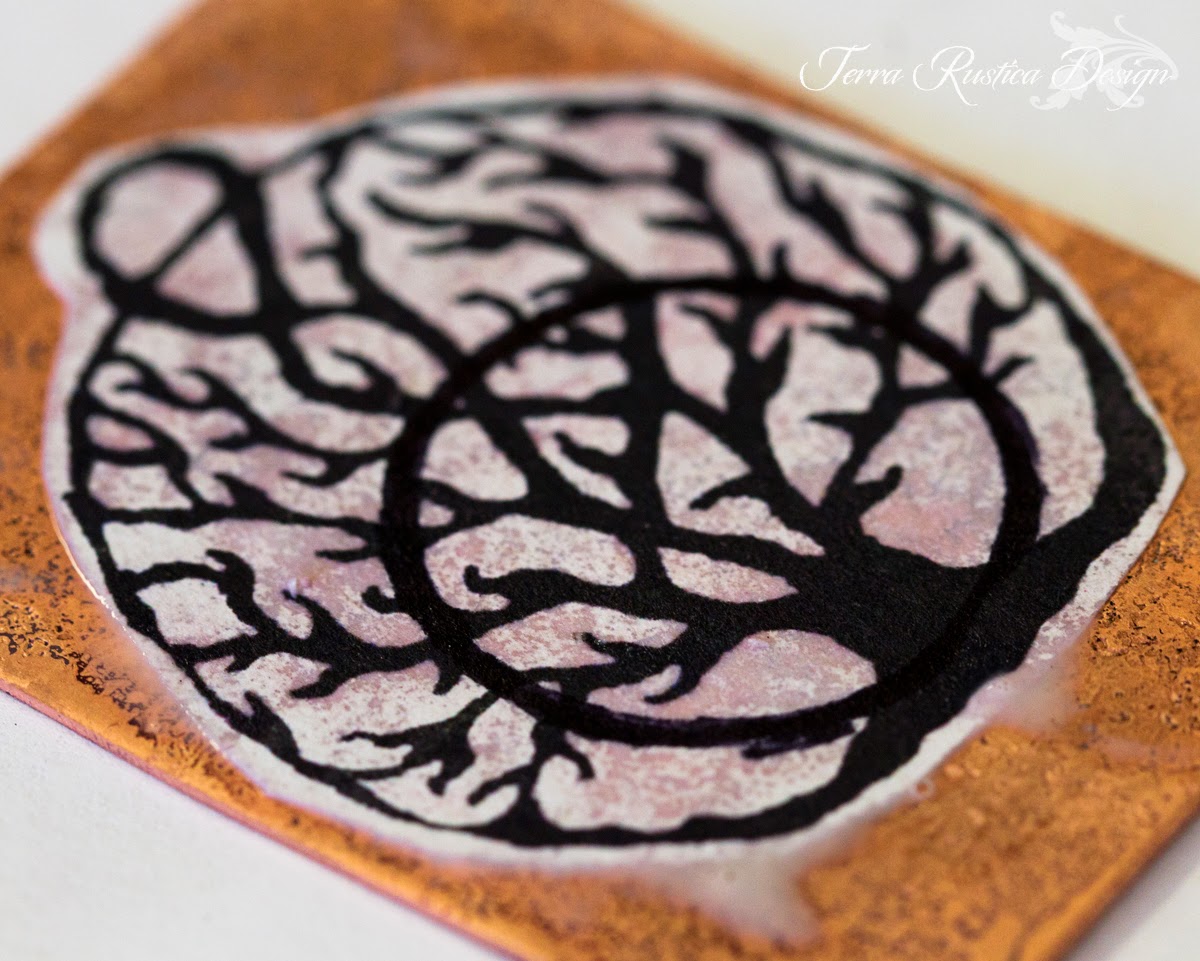

Print out your artwork and then glue to the front of your metal. I use a very sticky glue made for sandblasting, but I've seen some use Elmer's glue or Rubber cement. You can experiment here and see what works best for you. TIP: If are using a metal that has been work hardened, anneal it first. This will soften the metal and make your sawing much easier.

Sometimes you will have to reapply the glue if the paper starts to lift.

Step Two

Drill holes where you want to pierce. Here's a handy chart courtesy of Rio on blade sizes and how big your drill bit should be for each blade. Be safe and wear your goggles!

Step Three

Select your blade and load it into your saw frame. If you look at the above chart, it shows the different blades and thicknesses. So the 8/0 is the thinnest. For very fine work, you want a thinner blade. I use a 4/0 blade for my detailed designs. The only problem with thinner blades is you run the risk of breakage. This is where practice makes perfect comes in. You will want to start with thicker blades while you are learning and then graduate to thinner. It's also recommended to start with a cheaper metal for practicing. Although, just so you know, it's a dream to saw sterling silver because it cuts like butter.

For loading your blade into your frame, you want the blade teeth facing up and angled down, so when you cut out the metal, it cuts on the downward stroke. First, load the blade in the top and tighten the wing screw. Then thread blade through your pierced piece, keeping the design face up. Now place the frame into the v of your bench pin and press to apply tension. Place blade into bottom of frame and tighten wing screw. The blade should have a nice ping sound.

Step Four

Apply lubricant to the backside of your blade and begin to saw! For the lubricant, you can use a synthetic like Rio's popular Bur Life or bee's wax. I am using Thunderbird's synthetic beeswax block. It's easy for me to apply by just running the back of the blade along the block. The reason I only apply lubricant to the back is I don't want to gum up the teeth.

For sawing, hold the frame in your dominant hand, making sure the blade is straight up and down, or at a 45 degree angle to your piece. Hold the piece with your non-dominant hand. Keep your grip relaxed and your shoulders down while you saw. Try not to push the blade, it will do the cutting on the down stroke. When turning corners, move the piece slowly, keeping the blade moving up and down. You will notice when you need more lubricant because it starts to get harder to saw and the blade noise sounds a bit different.

Try not to twist the metal because it could break your blade. Also, keep blowing away all the metal dust so you can watch the blade closely.

Step Five

Remove your design and clean your piece! Next, you will want to use needle files to file away all the saw marks. Okay, now go saw some metal!

I have yet to complete this piece because my husband and I have been obsessed with ceramics!

In fact, he wants to share these beads and offer them for half off! He thinks because it's his first time that they aren't that good. I think they are gorgeous! So, if you see any sets you like feel free to check them out here for a great price! UPDATE: All beads have already sold. WOW! My husband is really excited! Thank you everyone!

Thank you for reading!

2 comments:

I will admit, it took me forever just to get the saw blade to "ping" just the right way! Although I use the saw much more often nowadays, it's definitely NOT my most favorite task - I must practice! That is a great tip on applying lubricant to the BACK of the teeth - I will try that next time!

Those beads are just gorgeous!

Thank you so much. So glad your hubby is happy 😊 I'll be back.

Post a Comment