Our winner for the fabulous pendant is KayzKreationz! Congrats!

Ceramic Bead Earrings Tutorial

by MaryAnn Carroll

Tools and Materials:

Copper wire (8 gauge) two pieces cut to 1 ½” lengths, (16 gauge) 1 piece cut to 8” length (you will not use all 8”), (20 gauge) two pieces cut to 8” lengths, 1 piece cut to 12” length

Ceramic bead disks (two approximately ¾” in diameter)

All-in-one solder paste (no need to use flux- low melting point- I recommend)

Wire cutters (strong enough to cut through 8 gauge wire)

Standard small household hammer

Chasing hammer

Jewelry pliers- flat nose and round nose

Polishing pad

Brass brush (soft)

Dremel sander or other sanding device (files will work)

Sand paper (150 grit)

Fire bricks

Torch and fuel

Bench block

Wooden dowel (1/3”) or another dowel-shaped household object

Ceramic bead disks (two approximately ¾” in diameter)

All-in-one solder paste (no need to use flux- low melting point- I recommend)

Wire cutters (strong enough to cut through 8 gauge wire)

Standard small household hammer

Chasing hammer

Jewelry pliers- flat nose and round nose

Polishing pad

Brass brush (soft)

Dremel sander or other sanding device (files will work)

Sand paper (150 grit)

Fire bricks

Torch and fuel

Bench block

Wooden dowel (1/3”) or another dowel-shaped household object

For those of you who do better with written directions, those are following the final picture.

I'll start off with a picture of the different styles of ceramic beads that would look great with the style that I will show you. For more designs using similar beads, look for Belle Armoire Jewelry magazine.... December 2011 issue.

Here is a completed pair~

The process in pictures~

To learn more about creating ear wires, click HERE and scroll down to the end of the tutorial.

And .... the written directions~

Technique (in order of pictures)

- Start with the two pre-cut 8 gauge wire pieces (1 ½”).

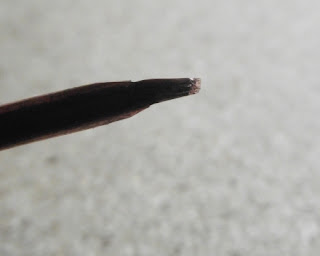

- Sand both ends to remove sharp edges

- Hammer the ends approximately ¼” from the tip. Flip the wire so that each side is getting hit evenly.

- Side view of the wire after 1st hammering

- Using household hammer, hammer the other end of the wire approximately ¾” – 1” from the tip. After flattening, use chasing hammer to continue to flatten to desired size. You can then use the ball end of hammer for texture.

- Sand the rough edges from the hammered end.

- Wrap the 16 gauge wire around the dowel until you have several pieces. You will only use two, but using a longer piece will be easier to work with when creating your own jump rings.

- With the tip of the wire cutter, cut the rings from the piece that you previously wrapped around the dowel.

- Jump rings will look similar to those in the picture.

- Sand the rough edges off of the jump rings while they are open. They may need to be opened further. For faster sanding use the dremel sander.

- Hammer two jump rings until you get the look you want. Be sure to hammer near the openings to easier soldering. Keep the openings apart, but barely touching each other.

- Apply the solder paste according to the directions on the package to the flattened ¼” side of the 8 gauge wire. Using either of your pliers carefully lay the wire down on the fire brick. Then, place the hammered jump ring carefully on top of the solder. Start heating the copper from the end as shown in the picture. Do not hold the torch in one place. Rather, use a waving motion over the piece. The solder will turn bright silver and bead meaning it is done. Using a quick solder requires much lower heat than regular solder. If done correctly, the soldered joint will be stronger than the metal itself. This can take some practice so if you are new to soldering, I would suggest practicing on scrap pieces first.

- Let the soldered piece sit for about 5-10 minutes.

- Once cooled, make a half loop with the 10” piece of 20 gauge wire. Keep an extra 2” that you will wrap around for the end. You will finish off the bottom half of the wrap with that.

- Continue wrapping to cover any visible solder.

- It is important to use large loops while wrapping wire in this style. Also, pull it through slowly, adjusting as you go. If you do this part too quickly, the wire will bend, kink and possibly break. You can use the flat nose pliers to pull it snug to the soldered piece.

- Use one of the 8” 20 gauge wires and make a loop in the center. You can use your fingers to squeeze the wire to make a pin head looking top.

- Put the wire on soldered piece as shown. This is where the bead will sit.

- Place both ends of the wire through the bead.

- Using your round nose pliers, make a loop in front of the second wire. Make one or two rotations AROUND the 2nd wire.

- Use your flat nose pliers to hold the loop in place while you begin making wraps using the other wire. You can continue to rotate this to your desired look.

- Leave some excess wire (3/4”) for a decorative look in front of the bead. This will also serve to keep the bead from rotating on the wire that was pulled through. You can hammer that piece or keep it rounded based on personal preference. Sand the end for a clean finish.

As always~

~Thank-you for supporting those who create handmade with handmade~

11 comments:

So cute MaryAnn!!!

Thanks Kristi!!!

I'm impressed, not only by the lovely earrings but that you are very good at written directions which is not an easy task at least not for me; have you thought about doing a video and posting it on your blog? Looking forward to more of your work...!

Those look like so much fun to make. Thanks for posting the tutorial. And thanks for Necklace giveaway. That pendant is awesome. I just sent you my info. I can't wait to wear it.

I am loving those earrings. But, you know, I'm the biggest fan of copper there is... Seriously, they are wonderful and so is the tutorial.

I have thought about doing a youtube video. I thought that I would have to speed the process up a bit so that it wouldn't be too long to watch. If I can put that all together, I'll be sure to post it here first...

Thanks for the compliment :o)

MaryAnn

Thank you for posting this very cool tutorial. The pictures and the writing look very well done. I am excited to try these.

What a great tutorial you made it look so easy!

This is a great tutorial! Thank you.

Thanks for the great tutorial - the pictures are very helpful!

so nicely written- great pics! Can;t wait to see you in print!!!!

Post a Comment