Welcome to our next BOOT CAMP! This go round we are going to show all sorts of amazing ways to create using cold connections. Cold connecting is awesome.

The term refers to joining metals and other materials without

heat. The minute I read Making Connections by Susan Lenart Kazmer, I was

totally hooked on using rivets and screws in jewelry connections. Especially since at that time I had never

used a torch and was actually too scared to try soldering. My, how times have changed! While I do a fair amount of soldering in my

work now, I still use cold connections whenever I can. They are quick; and require so much less finish

work than hot (solder) connections (no fire scale, no pickle!).

For the purposes of this post I will be discussing and

showing how to use micro screws in jewelry design. This boot camp is going to be full of cool

ideas (see what I did there??) so I hope you will follow all the Monday

posts—rivets are coming!

|

| A variety of designs I have created using micro screws... |

Micro screws are really gaining popularity in jewelry

design. Objects and Elements is a great

source for brass and steel micro screws and nuts in a variety of lengths. Nunn Design offers brass and copper micro

screws in a medium length. Just found

out about the copper—my order has been placed!

The screws come in a standard 1/16th size, listed at O and E

as short and long lengths. I usually

default to the long length; it’s easier to trim excess than to come up short

when stacking and connecting elements in your design.

The look of micro screws is a bit industrial, which I love,

but the screws are tiny enough not to overwhelm a design. They are perfect for connecting metals and

components that cannot be soldered together (aluminum, enameled elements),

great for adding delicate materials to a design (like paper or resin/plastics),

and wonderful to create elevated layers and stacks. I use micro screws almost exclusively for my line of aluminum

embellished cuffs. So, I will be showing

here how easy it is to make a really interesting cuff using a variety of

materials all held together with micro screws.

What you need tool-wise:

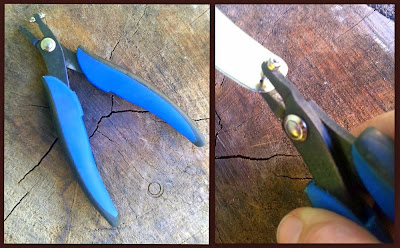

micro screws and nuts in your preferred metal, micro screwdriver, a Dremel, Flex Shaft or EuroPunch

tool with a 1/16th drill bit or setting, wire snips, metal shears, needle file, flat file, medium sanding sponge,

round end riveting hammer or chasing hammer, domed face chasing hammer, bench block, steel bracelet bender

or mandrel.

What you need materials-wise: 6 x 1.50 inch aluminum bracelet blank (available in many widths, this is just my favorite), 6 x 1 inch (or so) length metal of your choice to overlay (I am using tin from an old cookie container), embellishments (this can be beads, discs, charms, whatever you like, just make sure they have a 1/16th hole in them).

What you need materials-wise: 6 x 1.50 inch aluminum bracelet blank (available in many widths, this is just my favorite), 6 x 1 inch (or so) length metal of your choice to overlay (I am using tin from an old cookie container), embellishments (this can be beads, discs, charms, whatever you like, just make sure they have a 1/16th hole in them).

|

| Micro screwdriver, aluminum blank, brass micro screws and nuts, riveting hammer, curved chasing hammer, round nose hammer. |

|

| Bracelet blank after texturing. Using a hammer with a slightly curved face prevents metal marks from marring the interior of the cuff. |

Next, bend the aluminum into a cuff shape. I have a bracelet bender and it is so easy

and quick. Two bends and I’m ready to

go. I can’t live without my bracelet

bender. I like oval cuffs, but you may

prefer a round shape…do what you like!

|

| Blurry shot of the bender in use, then the finished shaped cuff. Adjust with your fingers as needed to get a perfect fit. |

Prep your metal overlay.

For this cuff I cut a length of patterned tin from an old cookie

container. I used metal shears to cut

the tin. I like a tapered look to the

overlay, so I cut mine a little narrower to one end. Make sure the metal is filed smooth on the

edges, especially with tin, leaving no snags or rough edges. I round the corners also. Sanding sponges work great here to finish and

soften edges quickly. If you are using

copper or brass, I suggest a lighter gauge than the aluminum base. I usually use 24 gauge copper and brass.

*Don’t panic—I’m listing sources at the end*

Drill or punch two holes at each end of your overlay metal,

then bend the metal over the aluminum cuff, centering the overlay top to bottom

and end to end. Once you have the metal

placed where you like, mark through the holes at one end to the aluminum using

a fine line Sharpie marker. Drill or

punch ONE marked hole in the aluminum, then insert a micro screw from the back

of the cuff, through the overlay and add a nut, then tighten. I learned to place a bit of tape over the

screw head to hold it in place. I have

dropped approximately 7,000 micro screws and nuts on the floor under my

bench. On the filthy, bead-ridden,

no-man’s land that is my floor…sigh...they are lost forever, or until I clean, so let's just go with FOREVER. Drill or punch the second hole and repeat with

another micro screw.

Now you have one end in place, smooth the overlay metal to

the other end, hold tightly and mark the other end with the Sharpie. Drill or punch one hole, insert the micro

screw, add the nut and tighten. Finish

by drilling or punching the last end hole and assembling the screw/nut as before.

Now you can really tighten the nuts to the screws. TIGHT!

I usually hold the excess screw material with my fingers or needle nose

pliers and tighten the nut with bent nose pliers until the nut won’t turn

anymore. Then snip the excess screw

material to about 2mm above the nut. Place

the cuff on a steel mandrel (I use my ring mandrel) and hammer the excess screw

material flush to the nut. Use a round

nose riveting hammer or round nose chasing hammer for this so the metal flares

and domes, securing the nut in place. Hammer at an angle, not straight down, to

flare and dome the excess metal. Feel it

with your finger—you want the metal to be smooth, no rough edges. Hit it with a sanding sponge to make it

smooth as needed.

You’re basically done!

Now the fun part, adding extras!

I love MaryAnn Carroll’s enamel discs and use them in most of my cuffs

(and just about everything else I make).

Here, I chose a nice big disc (1.25 inch) layered with a smaller round I

cut from the cookie container cover that I drilled and dapped, and another tiny

enamel disc. Be creative here! Layer large, flat beads, resin paper, stampings--whatever you

can think of--as long as it has a hole big enough for the micro screw. Position your base disc or bead where you

want it on the cuff (I like a slightly off-center asymmetrical look), mark the

spot with the Sharpie, then drill or punch a hole. This time, insert the micro screw through the

bead/disc stack from the top down so the screw head shows. Then insert the screw end into the aluminum,

add the nut to the back and tighten as tight as you can with your fingers. For the final tighten, use the micro

screwdriver inserted in the screw head, hold on to the nut with your fingers or

pliers, and tighten really snug. Snip

the excess screw material.

|

| Adding elements and using the micro screw driver. A handy little device! |

Now, here it can get interesting. If you use dapped discs like I did, you will

need to create a curved surface in order to set the nut. The screw head must be supported by a metal

surface in order to hammer without cracking or ruining your discs. So, here’s my solution because I don’t have a

ton of fancy tools. I simply place my

round nose hammer in a vise. Then I

invert the cuff, make sure the screw head is right on the ball of the hammer,

then hammer and flare the excess screw material to the nut using a riveting

hammer or another round nose hammer.

Yes, once you become addicted to riveting you will come up with all

kinds of contraptions to get the job done.

Again, make sure there are no rough spots or snags and you are DONE!

|

| It may not be elegant, but it works! |

|

| Definitely a balancing act, but you need to support the screw head while hammering from behind. Otherwise, you will crack and ruin your stacked elements! |

Cold connecting designs are as endless as your

imagination. I’m including pictures here

of some of my cold connected designs, and please visit our Pinterest page to

see cold connections created by other artists in and out of LMAJ. Come back often, we have more fantastic cold

connection tutorials scheduled exploring tube rivets, nail head rivets and

more.

Until next time—Keep Calm and Rivet ON!!!

|

| A recent and favorite assemblage pendant I created using micro screws and nail head tube rivets. More on those in future Monday boot camp posts! |

Sources:

Aluminum/Brass/Copper bracelet blanks: Gotta Getta Deal (check out the anodized aluminum in beautiful colors!)

EuroPunch Tool: These

are now available in many places including Michaels, Etsy, Objects and Elements

Dremel, micro screw driver and drill bits:

Any local hardware store

Sanding sponges: Local hardware stores

Sanding sponges: Local hardware stores

Copper enamel discs: MaryAnnCarroll/Artisan Beads Plus